Rapid prototype production is a vital piece of the aerospace and agricultural industries to name but a few. Companies in the space, usually because of a considerable need for research & development of patented creations, require CNC machine services. Three-dimensional milling, boring, turning, and threading of materials into complex components opens the door to custom manufacturing capabilities. Prototype production, in small and large batches, means being able to control costs and create on-demand.

Who Needs CNC Machine Development Assistance?

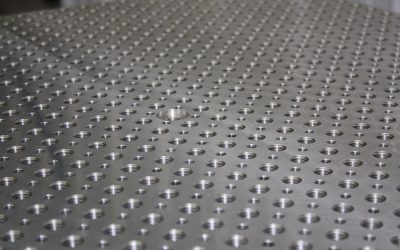

Computer numerical controlled or CNC machine services transform metal or plastic stock materials into various product designs using high-speed cutting machine tools. The tools work around the product, forming geometrically accurate shapes within the workspace based on computer aided design mechanics. Engineers, developers, and corporate designers are the parties most likely to seek out what is known as design-for-manufacturability services from CNC machine shops.

CNC Machining Metallic Alloys

Shop techs, in conjunction with the automatic design processes of the custom cutting machines, work on brass, bronze, copper, aluminum, and steel alloys of specific grades. For example, a machine shop may work with both Copper 260 and/or Copper 360; Aluminum 6061, 5052, and 2024 are popular and see much use on machine shop floors.

CNC and Plastic

Just like metal, plastic parts made out of acrylic, nylon, polypropylene, and polycarbonate feed engineering teams in the medical field for many reasons.