Have you been tasked to find the leaky problem that is causing your industrial production plant a fortune? Do you find it a challenge searching for the root cause as there are several components that may need to be repaired or replaced but are unsure how or where to start? If so, then here are two ways to help you effectively detect or determine the part of your pipeline system that requires repairs.

Hydrostatic Testing

One of the most effective ways to help you determine the location of the issue in your system is by performing a hydrostatic test. This type of test typically involves filling the system with a dyed liquid for visual leak detection. It also examines pressure tightness to further detect the problem area.

Acoustic Sensors

Another effective method to help you determine where your issues lie within your system is by utilizing acoustic sensors. These types of sensors are used to listen for leaks by monitoring the time difference between signals.

Detected and Diagnosed

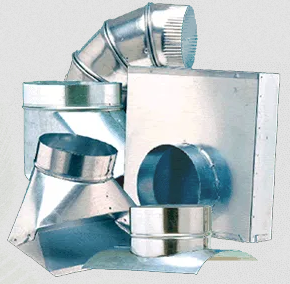

Perhaps you have used one or both of these methods and have finally found the location of the leak. Much to your surprise and delight, the only thing that needs to be repaired or replaced is your system’s fittings. You are now searching for a company that offers the highest quality industrial pipe fittings in the market but are unsure who you should acquire them from. When searching for an industrial pipe fittings supplier, consider purchasing from a highly reputable and reliable company that has been serving clients for several decades. Choosing this type of company will ensure you receive top-notch products and services.